Facility

Our 24-hour manufacturing operation functions in a 12,000 sq ft. facility. We have additional land at this location for an expansion of 40,000 sq ft. if needed. With injection molding, value added services, mold design, manufacturing, part design, and engineering services located under one roof, it is truly a unique one-stop facility to fulfill our customers requirements and expectations.

Toshiba All Electric 45, 85, 310 ton

Injection Molding

Our goal is to fully automate the manufacturing and/or assembly process with the use of robots for packaging and/or in-line dimensional checks. Our molding suite includes all electric Toshiba injection molding machines ranging from 45-310 tons with shot sizes from 1-29 oz. Each machine is equipped with air and hydraulic core pulls, Mold Master or Gammaflux temperature controllers, and valve gate controllers. The larger 310 ton injection molding machines are equipped with Sepro 5 axis robots and 6 station indexing conveyor systems. Multi-Shot secondary injection units are also available for overmolding capabilities. Two 5 ton overhead hoists are used for mold set-up and transportation.

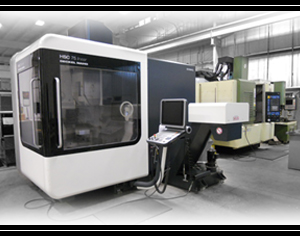

DMG HSC 5-axis | Makino V55 | Makino EDNC 43 EDM

Mold Manufacturing & Machining

Our high speed machining centers incorporate the latest tooling technologies and can produce extremely complex parts and ready to mold surface finishes. The highlights of our in-house machining suite includes a DMG HSC 5-axis high speed machining center, Makino V55 high speed machining center, Makino CNC EDM, Okada graphite electrode machining center, and various support equipment. A LaserStar laser welder is utilized to make revisions or repairs quickly and within our complete control.

Design & Programing

We utilize the latest cutting edge CAD, CAM, translation and verification software. Solidworks is our CAD software of choice, but we have the capability to translate additional file types: Catia, ProE, IGES, and STP. PowerMILL and Vericut are utilized to program our milling machines.