Quality

A strong and modern Quality Management System (QMS) is a standard prerequisite for today's manufactures. EEI understands the importance of a QMS and is continuously maintaining and improving our quality system and technology. Our QMS covers all RFQ's, the receipt of the initial order, all manufacturing processes (design engineering, mold manufacturing and PM programs, injection molding), testing, packaging, and final delivery for all products.

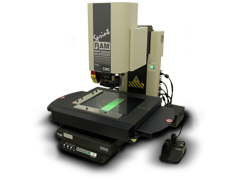

Ram Optical Sprint CNC 300 Vision (Measure-X)

Our precision inspection and testing equipment address a variety of dimensional and product specification and requirements. These requirements range from incoming inspection, final audits, first article inspection reports, and SPC studies.

Quality Objectives

Provide our customers with 100% on time delivery (OTD) of finished plastic components and molds.

"Zero Defect" on all finished plastic components.

Our Quality Control Specialist Are Trained In

ASQ Core Tools: APQP, FMEA, PPAP, MSA and SPC

Installation, Operation, Performance Qualification (IQ, OQ, PQ)

Full Dimensional (FAIR) and Geometric Dimensioning & Tolerance

Comprehensive Calibration Program and Gage R&R

DEA IOTA 1203 CMM (OpenDMIS)

Incoming, In-Process, and Final Inspection

Corrective and Preventative Action

In-Process Monitoring, CPK Runs

Traceability (Material and Manufacturing Lot)

Nonconforming Material Procedures

Continuous Improvement Program

Preventative Maintenance (Tooling and Equipment)

FAR / DFARS

ITAR

Contact Exact Engineering Inc, let us improve the quality of your product.