Injection Molding

- Production

- Scientific Injection Molding

Exact's production facility has the capability of operating 24 hours a day / 7 days a week, and is set up to handle low volume and high volume automated production. Our Toshiba all electric injection molding machines range from 45-310 tons with a shot size capability from 1-29 ounces. To aid in manufacturing, the larger 310 ton injection molding machines are equipped with Sepro 5-axis robots.

Diversity

Utilizing the latest innovations in custom injection molding, in combination with our years of experience, allows us to offer a variety of injection products and solutions.

Exact follows a scientific molding approach across all stages of the manufacturing process: part design and material selection, mold design and build, process development and production injection molding.

With the heart of the scientific injection molding process taking place during mold build and process development, we place extra emphasis to determine and control optimal plastic injection molding process parameters. Following this scientific approach eliminates variables that would result in defective or low quality parts, and creates a robust, predictable, and repeatable process that produces top quality parts.

Scientific injection molding has several benefits, including:

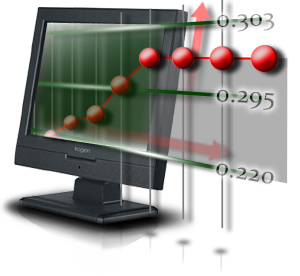

Gate Seal

- Consistent and Repeatable Process

- High Quality Parts

- Cycle Time Optimization

- Lower Piece Price

- Higher Output

- Process Documentation

Some of the process data and chart profiles analyzed include:

- Cavity Balancing

- Rheology Curve

- Gate Seal

- Melt and Mold Temperature

- DOE

- Cycle Time Optimization